TECHNICAL ADVICE

Support in choosing products suited to your needs

Support in choosing products suited to your needs

Mambretti Metalli has acquired a deep knowledge of its target sectors (non-ferrous metal foundries - the metallurgical industries, the mechanical workshops, the automotive sector and the agriculture sector) so much so that it now provides consultancy and support services on the types of products best suited to the different and needs of the customer.

The Customer does not know all the products that Mambretti Metalli markets and can rely on the professionalism of the Mambretti commercial network to support him in their choice. Mambretti's qualified staff guarantees a professional consultancy service, carried out by specialized technical personnel.

Specialized technicians at your service

Search for products suited to your needs

SERVICE

After-sales assistance service

After-sales assistance service

Mambretti Metalli guarantees a punctual and efficient assistance service even after the sale. The Customer is supported by qualified technical personnel in the correct use of the purchased products. All products marketed by Mambretti Metalli are certified and guaranteed according to current legislation.

After-sales technical personal assistance

Certified and guaranteed products

WAREHOUSING

Fast supplies with effective shipping

Fast supplies with effective shipping

One of the greatest strengths of Mambretti Metalli is the ability to satisfy its customers with on-time supplies, in a very short time.

Mambretti has large warehouses with large stocks of different types of products. This makes it possible to ensure that orders are processed in a very short time. Mambretti also verifies the effectiveness of shipments so that the Customer is always guaranteed a top quality service.

Supply quickly

Guaranteed shipping effectiveness

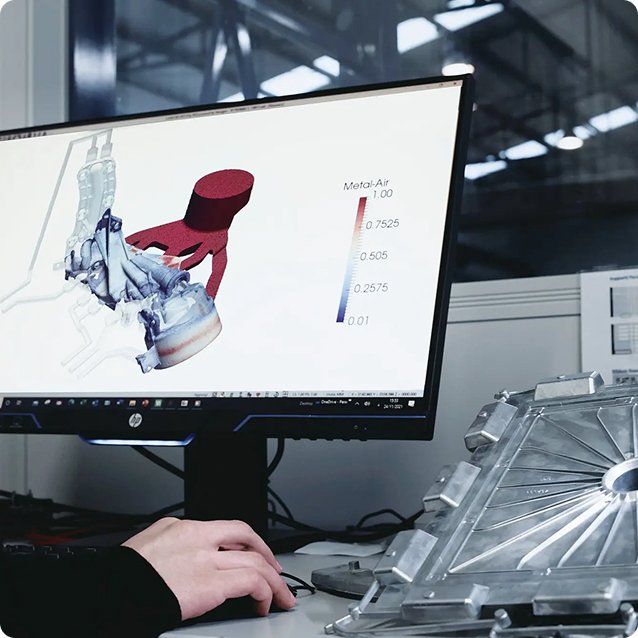

CASTING SIMULATION

Optimization and simulation software for the die casting process

Optimization and simulation software for the die casting process

Mambretti Metalli is the distributor of powerful software for casting simulation in non-ferrous metal die casting processes. It offers a die casting process simulation service, mold design modifications and advanced consultancy services to investigate possible defects and resolve them when the cost of the modification is minimal.

The CASTLE software suite is able to follow the mold maker and the foundry throughout all the design phases, arriving at the casting simulation, allowing the critical issues of the mold to be assessed in advance and appropriate improvements and corrections to be made.